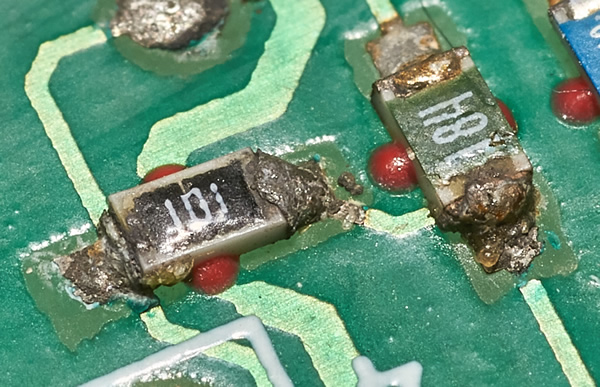

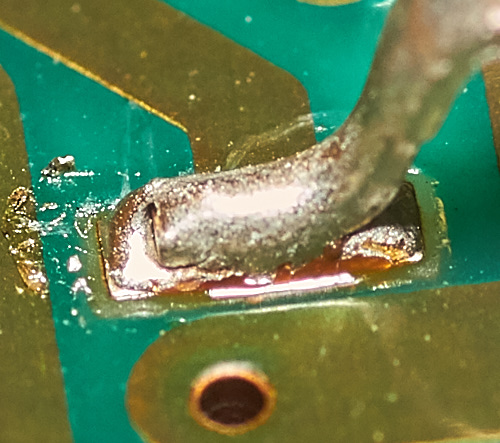

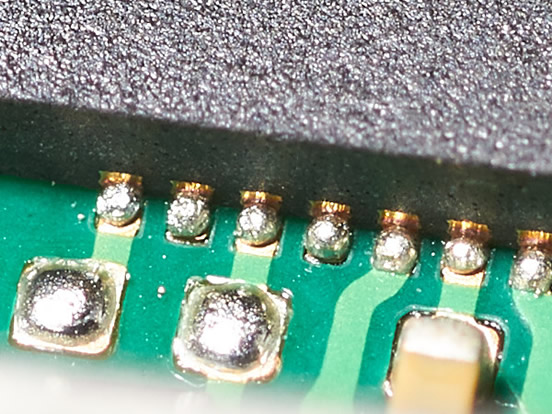

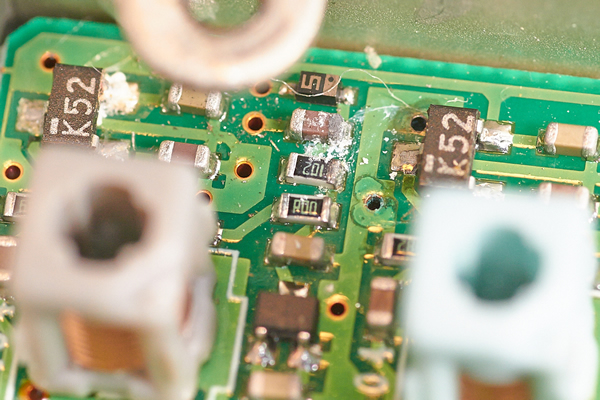

Bad SMD soldering. The capacitor was replaced with ceramic version on later models.

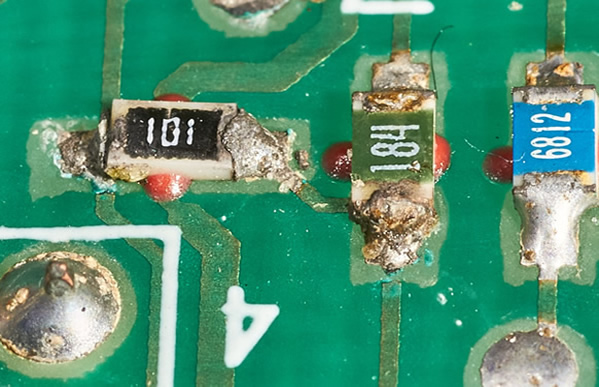

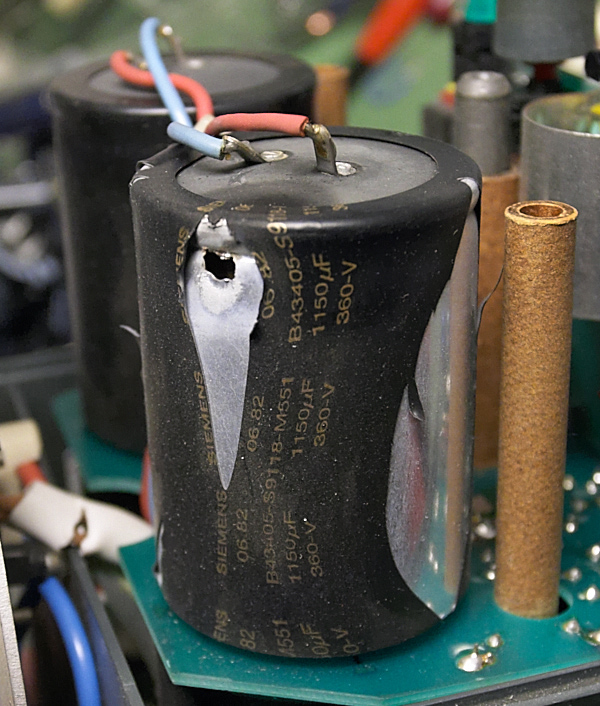

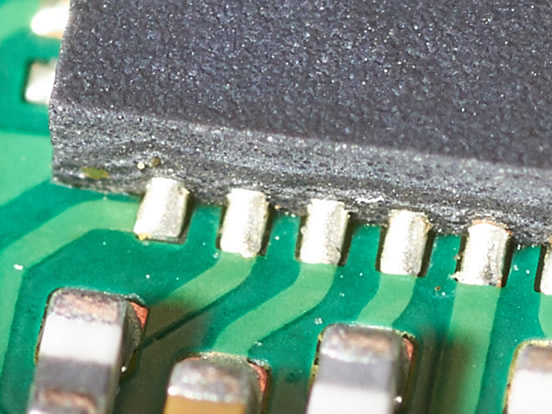

This shows severe acid damage on the Beolab 4000 active speaker. The acid

comes from the foam used to damp the speaker cabinet. But this black foam

it is not a stable material, and after 15 years, and specially where the

foam has been pressed against the PCB, the SMD components, resistors, and

part of the bare traces, shows severe damage! This is a standard-problem

on the Beolab 4000 speakers with the blak foam. The damage can be so

serious that a repair would not be worth it.

Indication of this problem: the speaker won't turn on, constant in st.by.

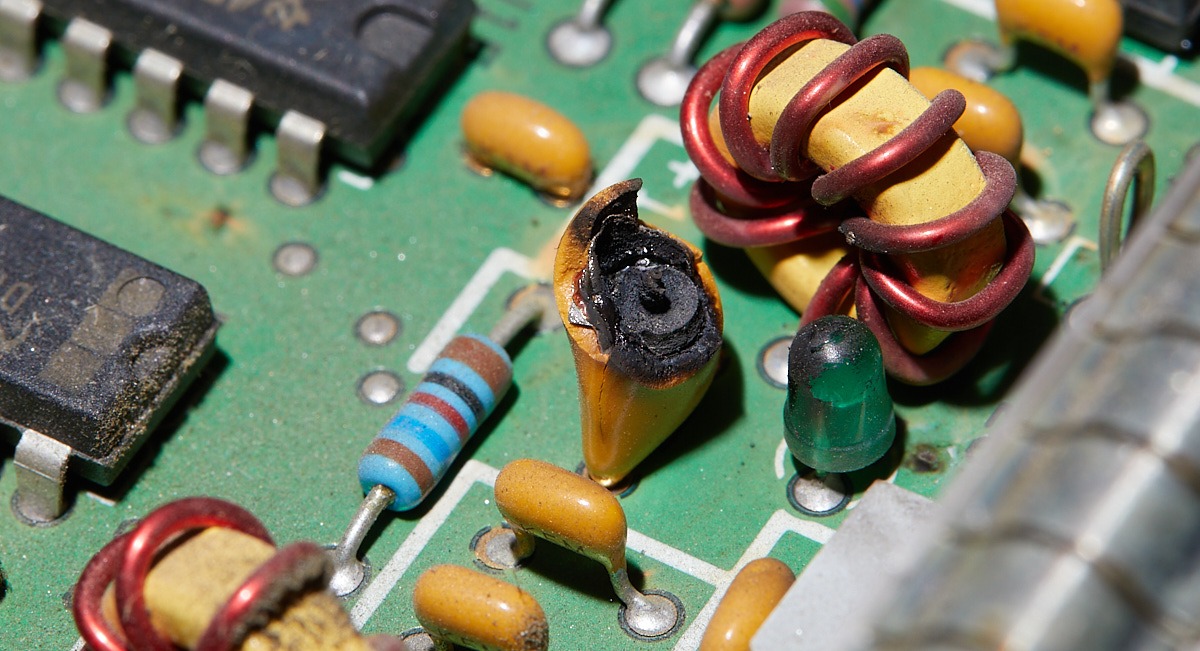

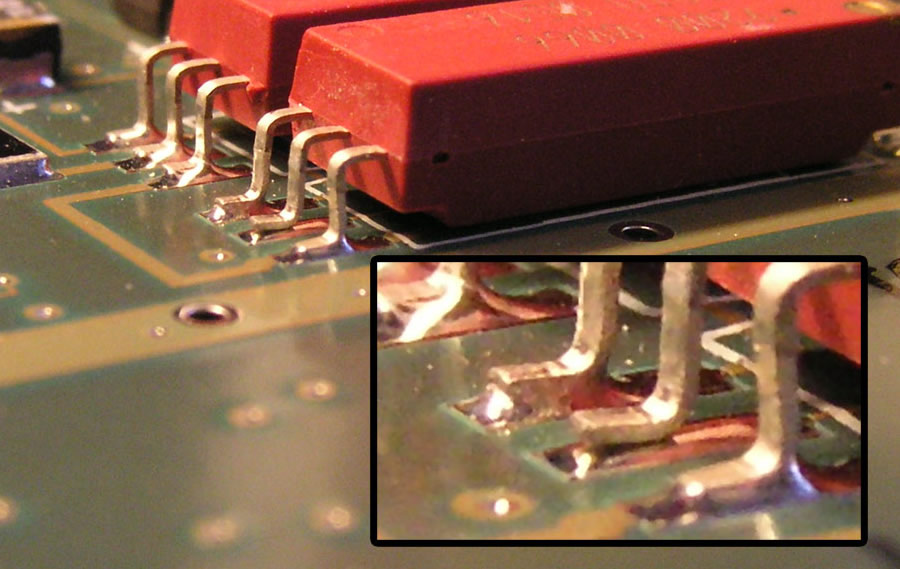

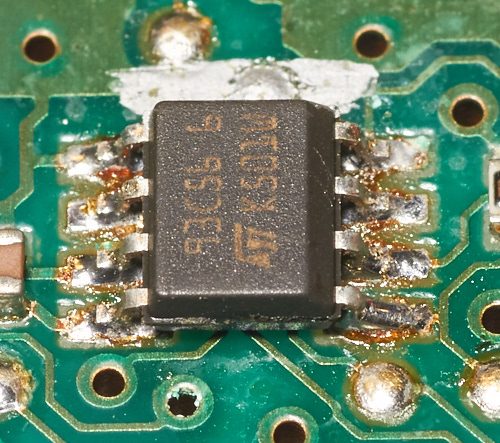

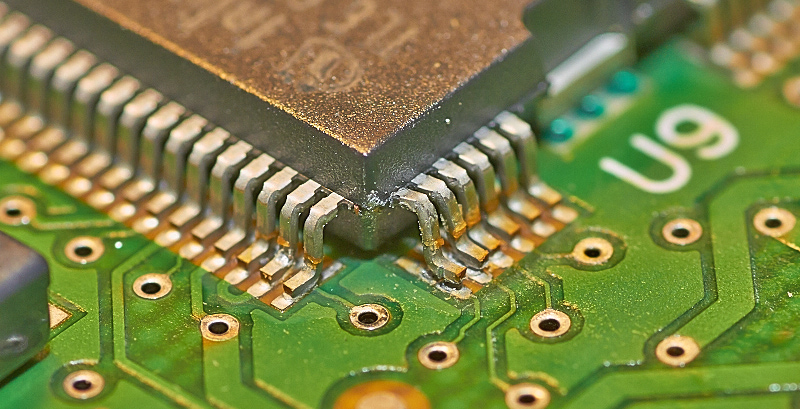

Wonderful solderings at dashboard PCB for a Renault Scenic 2 made by firm specialized in dashboard-repair in nordjylland. Price was "only" 2500kr+VAT and lasted 2 years.

Bad solderings on a IC inside a Engine Controller for a Opel Astra Stationcar. Allmost all the soldering was like mush, a oscilloscope probe could easily lift a pin from the pad - as the one right at the right of the corner. The engine worked, but a high speeds it stopped.

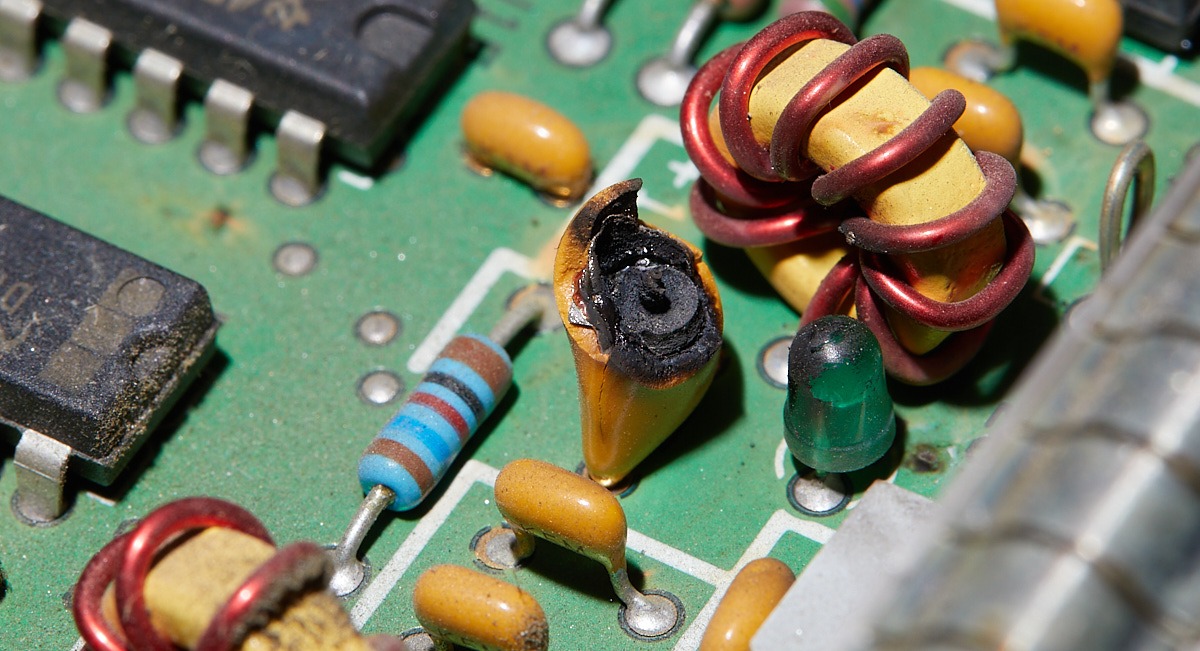

Lots of heat, lots of smoke!!! Standard fault on the old Broncolor Impact 41.

Typical soldering fault. Always causes problem with the equipment AFTER

the warranty expires. Picture before and after repair.

This is a VERY commen problem with the Samsung BD-E8500N (..among others)

Blueray/DVD recorder with tuner problems.

Typical problem for equipment exposed to heavy vibration. Heavy components

are glued to the PCB with hot-glue instead of epoxy. The leg are not

completely broke, but high-resistance causes ground loop hum. This is from

a Randall RG75 G3 Plus guitar amplifier, standard fault.

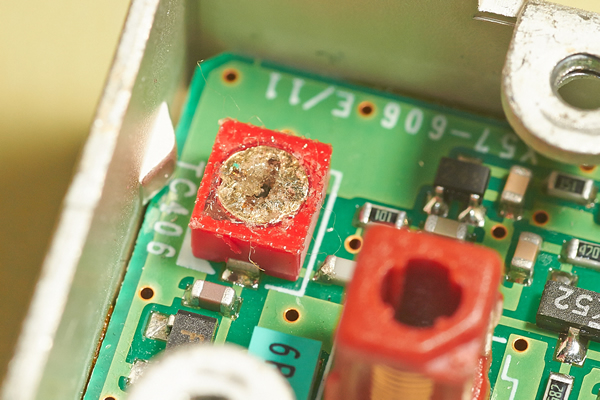

C-trimmers in very bad condition. These are very easy to break and are not

ment to be adjusted more than once or twice. Very common fault in the LO

section of TS-2000.

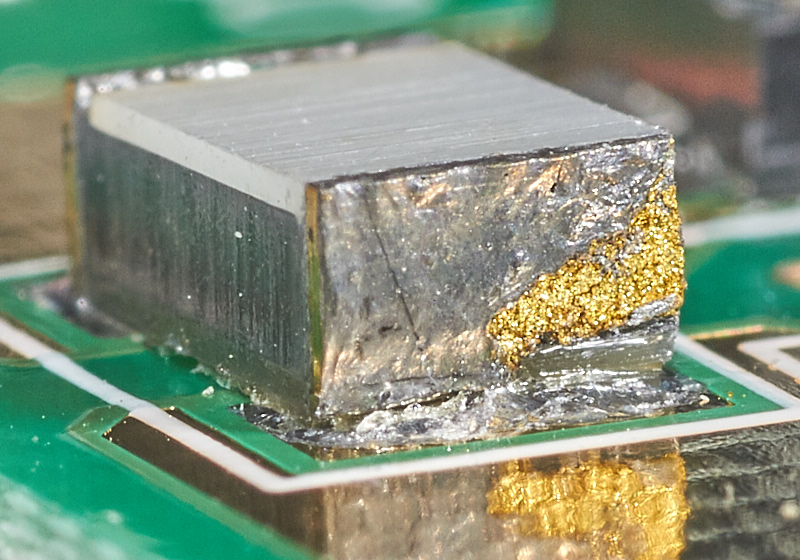

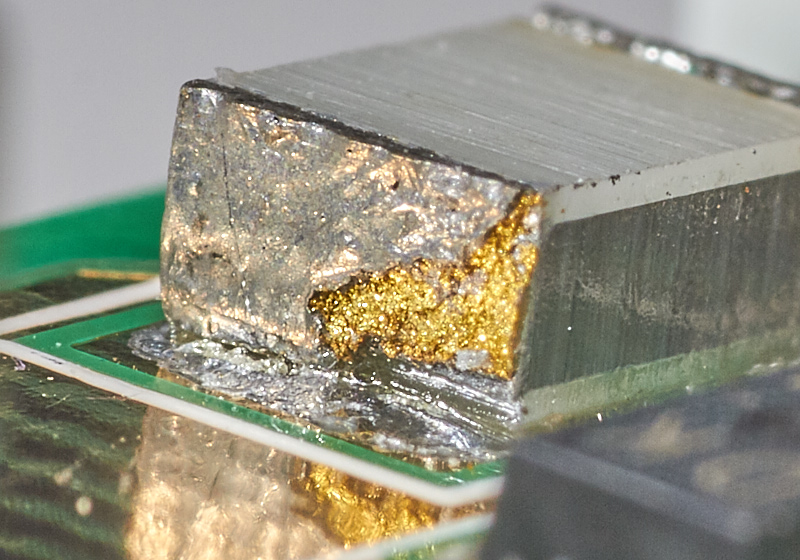

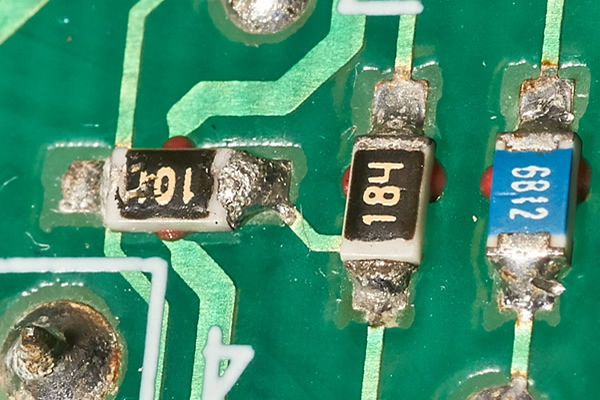

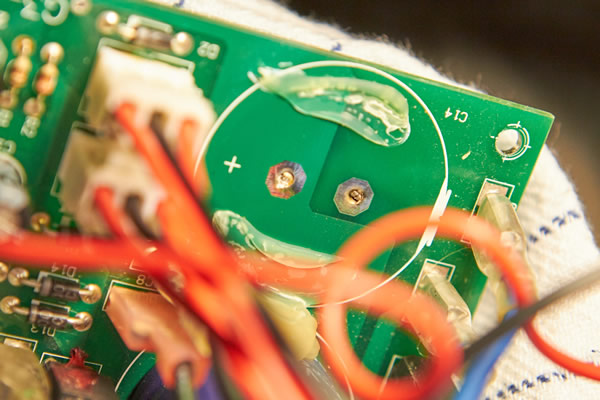

Acid damage at the LO PCB on the Kenwood TS-2000. This fault - and

intermittent faults on the trim caps leads to PLL failures on this unit.

Please note that because of this damage, there is NO thru hole connection

from the two vias on the PCB. The cooper inside the hole was completely

gone. This is a very common fault - bad soldering with acid, and very

often acid leaking from bad capacitors.

Go to frontpage of site - E-mail